When it comes to capturing big data to track and market your future business, Konnection software allows you to use a variety of collected data from your plant floor to make decisions for your business. Imagine being able to use PLC, equipment, process and ERP/MRP data to see past trends and analyze root cause and energy use over your entire process.

Production data is key to making sure your system is efficient and profitable. Konnection software turns your data into easy to read graphs detailing the information you have in a reviewable database created by your real-time production. This allows you to monitor production like never before. Recognize trends, view your total number of jobs and carriers, maximize shift productivity and track unproductive aspects of your floor.

Process tracking allows your company to ensure quality of your work and provides your operators detailed work instructions, the ability to compare shift reports and closely monitor energy and resource usage. Ensure that your parts went through the finishing system in the same amount of time every time. Use our software to check coating times, or when carriers entered and exited the system. With this information you can answer questions about what’s happening at every point in your process. With Konnection software, you’ll know everything about the process — even down to if your operator held or released the carrier within the allotted time.

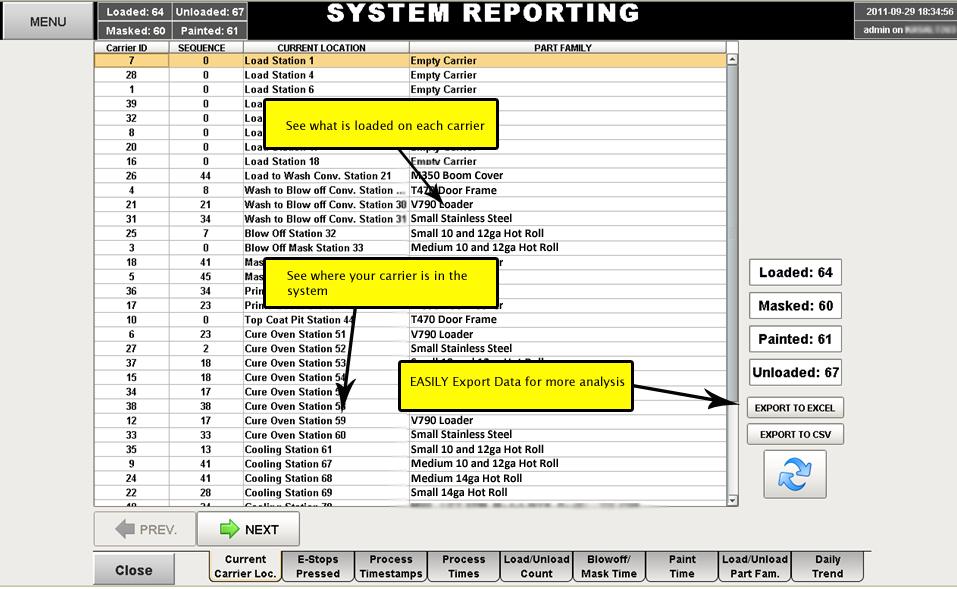

Tracking your parts is essential to making sure you are getting the most out of your process, and ultimately your business. With this level of system reporting, you can easily locate parts in the finishing system, and have their data accessible at a later date via serial numbers. An overview screen gives a visual representation of your stations and are color coded for quick detection for status review. You can see what is loaded on each carrier, where that carrier is in your system and then quickly export the selected data via spreadsheets or .csv files. Data can also be filtered by any field, allowing you to look at the production of a single part over a month or at all parts produced in a day.

Our Konnection software connects to your factory floor to your upper level software like SAP and your ERP seamlessly with the format of the data translated to read E-Net, DeviceNet, ProfiBus, ModBus, Serial and many more. The core of our software is SQL server that utilizes redundant servers, and is capable of using your existing hardware. This web-based software is visible from mobile devices and can even send text messages and alarms fault to the screens.

For more information on how you can maximize your plant floor, contact IntelliFinishing with your request for Konnection software.

Related posts

Search this blog

Get email updates

Archives

- April 2024

- August 2023

- May 2023

- April 2023

- March 2023

- June 2022

- May 2022

- April 2022

- November 2021

- October 2021

- September 2021

- April 2021

- March 2021

- January 2021

- October 2020

- August 2020

- June 2020

- May 2020

- February 2020

- January 2020

- December 2019

- October 2019

- September 2019

- June 2019

- May 2019

- March 2019

- February 2019

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- December 2016

- June 2016

- May 2016

- April 2016

- February 2016

- January 2016

- September 2015

- June 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- August 2014

- June 2014

- May 2014

- April 2014

- August 2013

- July 2013

- March 2013

- October 2012

- September 2012

- March 2011

- February 2011

- January 2011

- October 2010