How You Gamble With Your Paint Production Processes: 11 Ways To Be A High Roller

Transportation Waste is defined as the unnecessary movement of people or parts between processes.

Automated conveyors are usually not the first thing lean coordinators for manufacturing think of when they are developing a Lean strategy, but it can have a huge effect on Continuous Improvement.

I hope lean organizers (in any production facility which processes finished parts) consider the following information when beginning their lean journey.

Lean conveyance in manufacturing paint processes is more than moving parts from one place to another; it’s about eliminating unproductive waiting time by delivering parts to meet customer or station demand.

An IntelliFinishing complete finishing system is responsive to Lean manufacturing, focusing on optimizing product flow throughout the finishing process.

At IntelliFinishing, our unique Complete Powder Coating or Complete Liquid Coating System has the ability to compliment your Lean Manufacturing processes and eliminate waste in your facility, adding value to your products and your productivity measurements.

When thinking of an automated paint system, I hope you compare the benefits of all the types of conveyor systems available to you. See how an Intellifinishing system stacks up against monorail and power and free. Of course, I want you to choose our IntelliFinishing system if it is the best fit for your needs. Each conveyor has value for the processes in a manufacturer’s finishing system. The value added to your particular Lean expectation is dependent on what your requirements and end goals are.

Ways an IntelliFinishing Complete Paint System Reduces Transportation Waste for a Lean Process

If you are looking to cut transportation waste, an IntelliFinishing automated paint system may be what you are looking for. Here are some of the areas where you could be rolling “snake eyes” with every toss of the dice, (when you start up your production line for the workday), with an IntelliFinishing System.

- Batching product is no longer necessary and results in a reduction in WIP (work in progress):

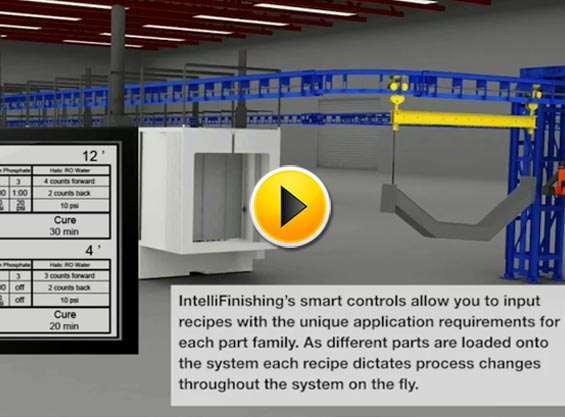

The IntelliFinishing system has immediate response when adjusting to process changes and production flow providing continuous improvement in your finishing process. It can even be extended to point of use, allowing your parts to travel from paint to assembly to shipping, improving your workflow. Our lean paint system allows for pre-programmed recipes that let you change process speeds and dwell times specific to the part and part family. - An IntelliFinishing system offers layout flexibility and grows with your production:

Several of our customers have added additional phases after their systems were installed, and efficiencies were recognized. Second and Third phases were implemented when necessary, instead of over-investing in the beginning. We equate this as “jackpot” for our customers! - Independent zones and carrier controls:

Our carriers can stop and start throughout the entire system, without stopping the rest of production, which saves you money! “Cha-ching!”

Carriers can stop and start in a process without affecting the rest of the line. - Single Piece flow or One Piece Flow is attainable:

An IntelliFinishing complete finishing system for manufacturers can attain single piece flow because it uses recipes to produce consistent and repeatable results. Our systems also have less than 1% downtime meaning you will be able to set and meet your required takt times. - Friction driven conveyor eliminates downtime due to chain issues:

Imagine a conveyor system that has a footprint that equates to one mile in length, filled to capacity with parts for the paint process (you are playing with a full deck!). Now imagine that somewhere within one of the zones there is a chain jam. If you work in production you probably have the ability to pinpoint exactly how long it takes to shut down production, find your pry-bar or heavy duty come-along (or whatever tool you have in place) to release the jam and physically pull the carrier in reverse to a buffer zone; perform the required maintenance; inspect the chain links as stated in your maintenance manual; all before you can restart production. As we have seen in plants, sometimes the jam fixes itself once the torque releases and operators will spray paint the section where the jam occurs and wait for that section to pass through the platform to inspect the chain for damage. Think about how many people on the paint line this affects and add in the costs of their downtime. “You got to know when to hold ‘em and know when to fold ‘em”. If this is something that happens frequently, you need to get more information about IntelliFinishing Automated Finishing Systems as soon as possible.

Our alternative to power and free conveyor has no chain. Reduce your maintenance, your floor space and downtime. - No wasted space on return chain because there is NO chain:

Return chain is a huge waste taking up valuable floor space. It can be a nightmare when troubleshooting. An IntelliFinishing Turnkey Finishing System’s unique “wild card” feature, is the ability to travel in forward AND REVERSE with no wasted movement such as a return chain that is empty having to travel through the whole footprint to get back to its original starting point. An IntelliFinishing system uses deadhead turns and spurs if parts need to be re-routed or receive extra processing. - Reduced downtime:

Or what we like to refer to as the “Royal Flush”. No chain. No jams. No operators waiting for production to restart. No de-dogging. Less maintenance. - Point of use:

An IntelliFinishing System gives you the ability to incorporate your work stations where you need them for your product flow. Masked parts can be unmasked at workstations located together for point of use in the production process to continue on their way immediately. You are in control to develop your personal lean strategy and what design works best for you when you “lay your bets on the table” with an IntelliFinishing design.

We can create a Lean layout for your finishing system that incorporates point of use into your production process. Click to enlarge. - No wasted movement of conveyor:

Our IntelliFinishing system, used by top manufacturers, offers your production line the ability to save on everyday wear and tear, plus maintenance costs, by not continuously running. If a part, or trolley is not present in a zone, the conveyor doesn’t run. We’re serious about saving companies as much as we can, unlike those other “jokers”. - Reduction in floor space:

IntelliFinishing “ups the ante” when you require a system that WILL fit into your available space, and we have proven it. One of our customer’s was told there was NO way they could fit an automated finishing system into the small space they had available. Our IntelliFinishing complete finishing system was designed just for that space, installed into that space and has been producing finished parts for more than two years! We have decreased floor space requirements by up to 43% in some instances (this was a large system install). - Uses shuttles and deadhead turns:

The use of shuttles and deadhead turns eliminates the need for large radius turns in your conveyor system, again resulting in reduced floor space. Our unique shuttle negates the need for huge turns to accommodate large part maneuverability and allows for easy expansion with no production downtime when you are ready to expand. We are “all in” when it comes to helping our customers save time, money and manpower when choosing a finishing system.

Shuttle and deadhead turns eliminate large radius turns resulting in reduced floor space usage.

Related posts

Search this blog

Get email updates

Archives

- April 2024

- August 2023

- May 2023

- April 2023

- March 2023

- June 2022

- May 2022

- April 2022

- November 2021

- October 2021

- September 2021

- April 2021

- March 2021

- January 2021

- October 2020

- August 2020

- June 2020

- May 2020

- February 2020

- January 2020

- December 2019

- October 2019

- September 2019

- June 2019

- May 2019

- March 2019

- February 2019

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- December 2016

- June 2016

- May 2016

- April 2016

- February 2016

- January 2016

- September 2015

- June 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- August 2014

- June 2014

- May 2014

- April 2014

- August 2013

- July 2013

- March 2013

- October 2012

- September 2012

- March 2011

- February 2011

- January 2011

- October 2010