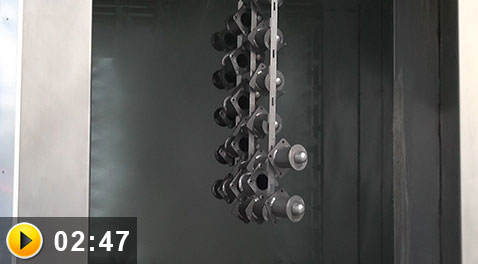

Smart Controls Monitor & Track Parts

Conveyors are the backbone of effective material handling. An automated finishing system can significantly reduce costs, drive throughput, increase productivity and even align with lean principles. Smarter controls can allow you to monitor and track your parts at any time, helping you to identify problem areas in your production line. This kind of data can be added for an additional cost to the system with a customized quote.

Production data allows you to pinpoint areas that are not running at complete efficiency, review recipes on the screen, such as Process Phase Times, Production Details, Parts List, Prime Stage-Trend (temperature & humidity), IR Stage Trend, Top Coat Stage Trend and Cure Stage Trend. If a recipe in your production list fails to meet the parameters of the recipe entered, smart controls flag it allowing you to select the carrier and review all of the data regarding that carrier throughout the system. You may also choose the Reporting option to print out a production report for review.

Additionally, smart controls along allow you to track individual parts to ensure that coating is applied to the specification of your customer.

With the addition of smart controls to your paint system, you can:

- review production data to identify bottlenecks

- ensure quality by reviewing environmental conditions (especially helpful for CARC process)

- use recipes to ensure parts are processed accurately

- review historical production and process data to compare shifts, schedule or employees

- display work instructions at operator stations