https://intellifinishing.com/wp-content/uploads/2025/06/temp-turning-corner-e1750706574738.jpg

228

200

marketing

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

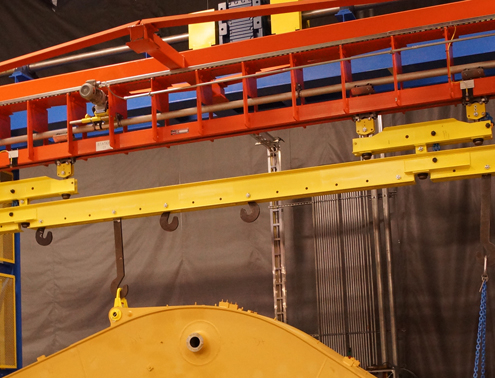

marketing2025-06-23 14:24:292025-06-23 14:37:45How do IntelliFinishing Systems turn corners?

https://intellifinishing.com/wp-content/uploads/2025/06/temp-turning-corner-e1750706574738.jpg

228

200

marketing

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

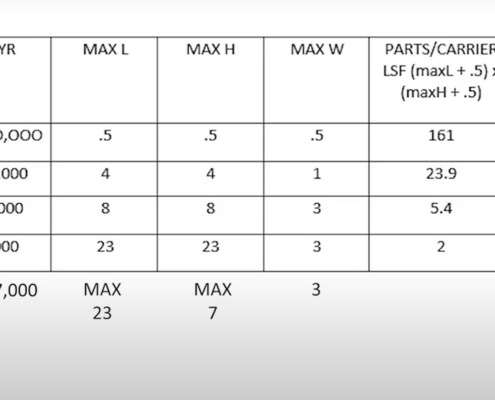

marketing2025-06-23 14:24:292025-06-23 14:37:45How do IntelliFinishing Systems turn corners? https://intellifinishing.com/wp-content/uploads/2025/06/Screenshot-2025-06-12-153645.jpg

793

1741

marketing

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

marketing2025-06-12 15:51:272025-06-19 15:37:32Navigating Industrial Finishing: The Art and Science of Estimating Capacity

https://intellifinishing.com/wp-content/uploads/2025/06/Screenshot-2025-06-12-153645.jpg

793

1741

marketing

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

marketing2025-06-12 15:51:272025-06-19 15:37:32Navigating Industrial Finishing: The Art and Science of Estimating Capacity https://intellifinishing.com/wp-content/uploads/2025/04/auto.jpg

600

1034

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-06-19 15:39:47IntelliFinishing is a part of Kasa

https://intellifinishing.com/wp-content/uploads/2025/04/auto.jpg

600

1034

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-06-19 15:39:47IntelliFinishing is a part of Kasa https://intellifinishing.com/wp-content/uploads/2025/04/part-window.jpg

365

980

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:04How Important is Part Window in a Finishing System?

https://intellifinishing.com/wp-content/uploads/2025/04/part-window.jpg

365

980

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:04How Important is Part Window in a Finishing System? https://intellifinishing.com/wp-content/uploads/2025/04/steel-ibeams.jpg

1333

2000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:04Steel Prices and the Impact on Finishing Systems

https://intellifinishing.com/wp-content/uploads/2025/04/steel-ibeams.jpg

1333

2000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:04Steel Prices and the Impact on Finishing Systems https://intellifinishing.com/wp-content/uploads/2025/04/maytag-IF-scott.jpg

866

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:07Delivering Responsive 24/7 Support

https://intellifinishing.com/wp-content/uploads/2025/04/maytag-IF-scott.jpg

866

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:07Delivering Responsive 24/7 Support https://intellifinishing.com/wp-content/uploads/2025/04/scada.jpg

699

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

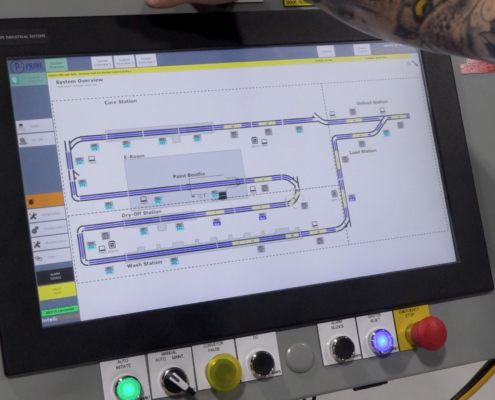

Justin Smith2025-04-24 11:08:032025-04-24 11:08:09SCADA and Finishing Systems: Gathering Real-Time Data and What to Do with It

https://intellifinishing.com/wp-content/uploads/2025/04/scada.jpg

699

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:09SCADA and Finishing Systems: Gathering Real-Time Data and What to Do with It

*Batteries Not Included: Explore What Comes with Automated Finishing Systems Before You Purchase

https://intellifinishing.com/wp-content/uploads/2025/04/par-for-the-course.jpg

798

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:11Changing Course Is Par for the Course

https://intellifinishing.com/wp-content/uploads/2025/04/par-for-the-course.jpg

798

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:11Changing Course Is Par for the Course https://intellifinishing.com/wp-content/uploads/2025/04/jr-wheel.jpg

648

800

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:13Endless Flexibility, Huge Competitive Advantage

https://intellifinishing.com/wp-content/uploads/2025/04/jr-wheel.jpg

648

800

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:13Endless Flexibility, Huge Competitive Advantage https://intellifinishing.com/wp-content/uploads/2025/04/faq.jpg

703

1400

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:14FAQ2: More In-Depth Answers to Common IntelliFinishing Questions

https://intellifinishing.com/wp-content/uploads/2025/04/faq.jpg

703

1400

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:14FAQ2: More In-Depth Answers to Common IntelliFinishing Questions https://intellifinishing.com/wp-content/uploads/2023/04/throughput.jpg

523

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:16Defining Throughput Needs is a Must before Designing a Finishing System

https://intellifinishing.com/wp-content/uploads/2023/04/throughput.jpg

523

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:16Defining Throughput Needs is a Must before Designing a Finishing System

IntelliFinishing Systems and Part Density Go Together Like Eggs and Bacon, with Racking as the Gravy on Top

https://intellifinishing.com/wp-content/uploads/2023/08/cat-blade.jpg

399

600

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:16How IntelliFinishing Revolutionized Finishing Systems

https://intellifinishing.com/wp-content/uploads/2023/08/cat-blade.jpg

399

600

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:16How IntelliFinishing Revolutionized Finishing Systems https://intellifinishing.com/wp-content/uploads/2023/08/simulation.jpg

358

848

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:17IntelliFinishing Simulation: Optimizing Throughput for Large Finishing Systems

https://intellifinishing.com/wp-content/uploads/2023/08/simulation.jpg

358

848

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:17IntelliFinishing Simulation: Optimizing Throughput for Large Finishing Systems https://intellifinishing.com/wp-content/uploads/2025/04/if-hmi-smart-controls.jpg

1357

2299

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:17The IntelliFinishing Difference: The Power of Smart Controls in Finishing Systems

https://intellifinishing.com/wp-content/uploads/2025/04/if-hmi-smart-controls.jpg

1357

2299

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:17The IntelliFinishing Difference: The Power of Smart Controls in Finishing Systems https://intellifinishing.com/wp-content/uploads/2024/05/hmi-operator-intellifinishing-sm.jpg

605

1080

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:20Prime Powder Coating featured in PCT Magazine

https://intellifinishing.com/wp-content/uploads/2024/05/hmi-operator-intellifinishing-sm.jpg

605

1080

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:08:032025-04-24 11:08:20Prime Powder Coating featured in PCT Magazine https://intellifinishing.com/wp-content/uploads/2025/04/Meet-IntelliFinishings-247-Service-Team.jpg

854

1280

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:27Always On-Call: Meet IntelliFinishing’s 24/7 Service Team

https://intellifinishing.com/wp-content/uploads/2025/04/Meet-IntelliFinishings-247-Service-Team.jpg

854

1280

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:27Always On-Call: Meet IntelliFinishing’s 24/7 Service Team https://intellifinishing.com/wp-content/uploads/2025/04/Save-Hundreds-of-Thousands-on-Operational-Costs-with-IntelliFinishing.jpg

864

1280

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:29Save Hundreds of Thousands on Operational Costs with IntelliFinishing

https://intellifinishing.com/wp-content/uploads/2025/04/Save-Hundreds-of-Thousands-on-Operational-Costs-with-IntelliFinishing.jpg

864

1280

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:29Save Hundreds of Thousands on Operational Costs with IntelliFinishing https://intellifinishing.com/wp-content/uploads/2025/04/For-Finishing-Systems-Smart-Controls-Are-A-Smart-Idea.jpg

1181

2463

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:31For Finishing Systems, Smart Controls Are A Smart Idea

https://intellifinishing.com/wp-content/uploads/2025/04/For-Finishing-Systems-Smart-Controls-Are-A-Smart-Idea.jpg

1181

2463

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:31For Finishing Systems, Smart Controls Are A Smart Idea https://intellifinishing.com/wp-content/uploads/2025/04/large-parts-belt-motor.jpg

378

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:33IntelliFinishing System Maintenance from the Customer Perspective

https://intellifinishing.com/wp-content/uploads/2025/04/large-parts-belt-motor.jpg

378

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:33IntelliFinishing System Maintenance from the Customer Perspective https://intellifinishing.com/wp-content/uploads/2025/04/mri-overview-1.png

474

839

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

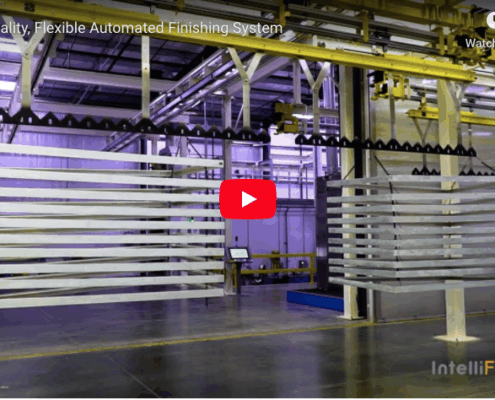

Justin Smith2025-04-24 11:07:272025-04-24 11:07:34High-Quality, Flexible Automated Finishing System

https://intellifinishing.com/wp-content/uploads/2025/04/mri-overview-1.png

474

839

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:34High-Quality, Flexible Automated Finishing System https://intellifinishing.com/wp-content/uploads/2025/04/mri-testimonial-1.png

474

840

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:40Customer Testimonial – Extremely Satisfied

https://intellifinishing.com/wp-content/uploads/2025/04/mri-testimonial-1.png

474

840

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:40Customer Testimonial – Extremely Satisfied https://intellifinishing.com/wp-content/uploads/2025/04/loadtrail.jpg

562

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:46How IntelliFinishing Shuttle Systems Address Unique Manufacturing Challenges

https://intellifinishing.com/wp-content/uploads/2025/04/loadtrail.jpg

562

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:46How IntelliFinishing Shuttle Systems Address Unique Manufacturing Challenges https://intellifinishing.com/wp-content/uploads/2025/04/mri4.jpg

492

750

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:46Case Study: Boost Flexibility, Quality and More with IntelliFinishing

https://intellifinishing.com/wp-content/uploads/2025/04/mri4.jpg

492

750

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:46Case Study: Boost Flexibility, Quality and More with IntelliFinishing https://intellifinishing.com/wp-content/uploads/2025/04/intellifinishing-system.jpg

499

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:47Flexible Finishing Systems with Proven Technology

https://intellifinishing.com/wp-content/uploads/2025/04/intellifinishing-system.jpg

499

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:47Flexible Finishing Systems with Proven Technology https://intellifinishing.com/wp-content/uploads/2025/04/pct-cover-June2020.jpg

833

615

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:48Finishing Systems & Statistics – Feature Article in PCT

https://intellifinishing.com/wp-content/uploads/2025/04/pct-cover-June2020.jpg

833

615

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:48Finishing Systems & Statistics – Feature Article in PCT https://intellifinishing.com/wp-content/uploads/2025/04/inhouse-vs-outsource.jpg

662

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:49Finishing: Outsourcing vs In-House

https://intellifinishing.com/wp-content/uploads/2025/04/inhouse-vs-outsource.jpg

662

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:49Finishing: Outsourcing vs In-House https://intellifinishing.com/wp-content/uploads/2025/04/dive-in.jpg

800

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:49Why Invest in a New Finishing System?

https://intellifinishing.com/wp-content/uploads/2025/04/dive-in.jpg

800

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:49Why Invest in a New Finishing System? https://intellifinishing.com/wp-content/uploads/2025/04/shutterstock_573520744-sm.jpg

1200

1800

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:51How to Double the Throughput Capacity of an Automated Finishing System

https://intellifinishing.com/wp-content/uploads/2025/04/shutterstock_573520744-sm.jpg

1200

1800

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:51How to Double the Throughput Capacity of an Automated Finishing System

JR Custom Metal Products Further Elevates Operations and Efficiency with IntelliFinishing System

https://intellifinishing.com/wp-content/uploads/2025/04/planning-delays.jpg

568

900

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:54The Best Laid Plans of Mice and Engineers

https://intellifinishing.com/wp-content/uploads/2025/04/planning-delays.jpg

568

900

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:54The Best Laid Plans of Mice and Engineers https://intellifinishing.com/wp-content/uploads/2025/04/part-density-bus.jpg

848

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:55How to Increase Part Density, Reduce Sway and More with VFD Controlled Carriers

https://intellifinishing.com/wp-content/uploads/2025/04/part-density-bus.jpg

848

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:55How to Increase Part Density, Reduce Sway and More with VFD Controlled Carriers https://intellifinishing.com/wp-content/uploads/2025/04/abcs-of-vfds.jpg

523

926

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:56The ABCs of VFDs (Variable Frequency Drives)

https://intellifinishing.com/wp-content/uploads/2025/04/abcs-of-vfds.jpg

523

926

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:56The ABCs of VFDs (Variable Frequency Drives) https://intellifinishing.com/wp-content/uploads/2025/04/hyster-robots.jpg

576

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:57The Advantages of Using Robots in Finishing with an IntelliFinishing System

https://intellifinishing.com/wp-content/uploads/2025/04/hyster-robots.jpg

576

1200

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:57The Advantages of Using Robots in Finishing with an IntelliFinishing System https://intellifinishing.com/wp-content/uploads/2025/04/if-system-banner.jpg

473

928

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:59When Should You take a Site Visit when Planning a New Finishing System?

https://intellifinishing.com/wp-content/uploads/2025/04/if-system-banner.jpg

473

928

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:07:59When Should You take a Site Visit when Planning a New Finishing System? https://intellifinishing.com/wp-content/uploads/2025/04/ir-ray.jpg

325

990

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:08:00Why Don’t More IntelliFinishing Systems Use IR Ovens?

https://intellifinishing.com/wp-content/uploads/2025/04/ir-ray.jpg

325

990

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:272025-04-24 11:08:00Why Don’t More IntelliFinishing Systems Use IR Ovens? https://intellifinishing.com/wp-content/uploads/2025/04/Smart-Controls-finishing-process.jpg

701

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:18Smart Controls: A Better, Faster, Smarter Finishing Process

https://intellifinishing.com/wp-content/uploads/2025/04/Smart-Controls-finishing-process.jpg

701

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:18Smart Controls: A Better, Faster, Smarter Finishing Process https://intellifinishing.com/wp-content/uploads/2025/04/IntelliFinishing-Leaves-Traditional-Finishing-in-the-Dust.jpg

400

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:19IntelliFinishing Leaves Traditional Finishing in the Dust

https://intellifinishing.com/wp-content/uploads/2025/04/IntelliFinishing-Leaves-Traditional-Finishing-in-the-Dust.jpg

400

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:19IntelliFinishing Leaves Traditional Finishing in the Dust

Infographic Will Help You Start to Determine the Best Type Automatic Finishing System to Consider

https://intellifinishing.com/wp-content/uploads/2025/04/Conveyor-System-Evolution-IntelliFinishing-Podcast.jpg

638

1346

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:19Conveyor System Evolution IntelliFinishing Podcast

https://intellifinishing.com/wp-content/uploads/2025/04/Conveyor-System-Evolution-IntelliFinishing-Podcast.jpg

638

1346

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:19Conveyor System Evolution IntelliFinishing Podcast https://intellifinishing.com/wp-content/uploads/2025/04/When-It-Comes-to-Finishing-Systems-Being-In-the-Know-Matters.jpg

640

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:20When It Comes to Finishing Systems, Being “In the Know” Matters

https://intellifinishing.com/wp-content/uploads/2025/04/When-It-Comes-to-Finishing-Systems-Being-In-the-Know-Matters.jpg

640

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:20When It Comes to Finishing Systems, Being “In the Know” Matters

Introducing The Pathfinder – A Complete, Automated and Affordable Flexible Powder Finishing System

https://intellifinishing.com/wp-content/uploads/2025/04/Dont-Miss-Our-Presentation-on-Automated-Finishing-Systems-at-FABTECH-2018.jpg

358

980

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:21Don’t Miss Our Presentation on Automated Finishing Systems at FABTECH 2018

https://intellifinishing.com/wp-content/uploads/2025/04/Dont-Miss-Our-Presentation-on-Automated-Finishing-Systems-at-FABTECH-2018.jpg

358

980

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:21Don’t Miss Our Presentation on Automated Finishing Systems at FABTECH 2018 https://intellifinishing.com/wp-content/uploads/2025/04/IntelliFinishing-Partnership-with-Caterpillar-Continues-to-Deliver-Results.jpg

664

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:21IntelliFinishing Partnership with Caterpillar Continues to Deliver Results

https://intellifinishing.com/wp-content/uploads/2025/04/IntelliFinishing-Partnership-with-Caterpillar-Continues-to-Deliver-Results.jpg

664

1000

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:21IntelliFinishing Partnership with Caterpillar Continues to Deliver Results https://intellifinishing.com/wp-content/uploads/2025/04/John-Claman-video-thumbnail.png

327

313

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:21Flexible Finishing? It’s possible with IntelliFinishing! – Podcast

https://intellifinishing.com/wp-content/uploads/2025/04/John-Claman-video-thumbnail.png

327

313

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:21Flexible Finishing? It’s possible with IntelliFinishing! – Podcast https://intellifinishing.com/wp-content/uploads/2025/04/Finishing-Systems-Automation-Which-Level-Is-Right-for-You.png

1080

1920

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:22Finishing Systems Automation: Which Level Is Right for You?

https://intellifinishing.com/wp-content/uploads/2025/04/Finishing-Systems-Automation-Which-Level-Is-Right-for-You.png

1080

1920

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:22Finishing Systems Automation: Which Level Is Right for You?

IntelliFinishing Designs Flexible, Modern Powder Coating System for Metal Fabricator, Reducing Costs and Improving Quality

https://intellifinishing.com/wp-content/uploads/2025/04/hytrol-logo-sm.jpg

225

500

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:22Hytrol Replaces Power and Free System with IntelliFinishing System

https://intellifinishing.com/wp-content/uploads/2025/04/hytrol-logo-sm.jpg

225

500

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:22Hytrol Replaces Power and Free System with IntelliFinishing System https://intellifinishing.com/wp-content/uploads/2025/04/hytrol-logo-sm.jpg

225

500

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:22Hytrol Increases Production 33% with IntelliFinishing System

https://intellifinishing.com/wp-content/uploads/2025/04/hytrol-logo-sm.jpg

225

500

Justin Smith

https://www.intellifinishing.com/wp-content/uploads/2024/12/logo.png

Justin Smith2025-04-24 11:07:182025-04-24 11:07:22Hytrol Increases Production 33% with IntelliFinishing System