Flexible, Automated, Conveyorized Finishing Systems

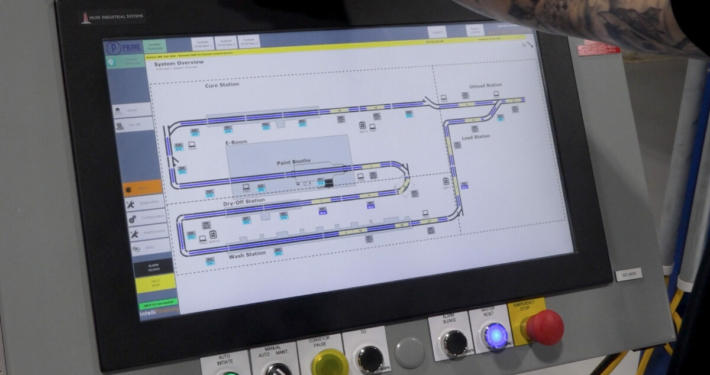

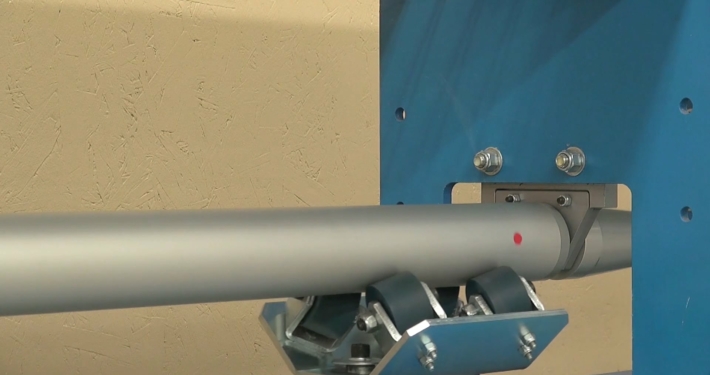

The IntelliFinishing system is a cutting-edge powder coating and liquid paint finishing solution that uses friction-driven conveyors and smart controls to optimize production efficiency. Its modular design allows for easy customization and quick installation, adapting to various part sizes and process requirements. Ideal for custom coaters and manufacturers, our customers consistently praise its reliability, minimal maintenance needs, and ability to enhance productivity.