Navigating Industrial Finishing: The Art and Science of Estimating Capacity

Being an industrial manufacturing leader means making informed decisions to streamline operations. This is no different when it comes to selecting and implementing a new finishing system. But how can a company determine the required system capacity? The answer lies in understanding your unique product mix and the capabilities of modern conveyorized systems like IntelliFinishing.

Diverse Product Mix? No Problem

Industrial manufacturing can involve an assortment of products of varying sizes and shapes. A single conveyorized finishing system, traditionally gauged by its feet per minute capacity, often poses difficulties in accommodating such product diversity. IntelliFinishing is a versatile finishing system that adapts more easily to a broad range of products, from small components to heavy oversized machinery parts.

Carriers Per Hour: A New Metric for Estimating Capacity

The traditional ‘feet per minute’ evaluation used by traditional monorail systems isn’t as

relevant for IntelliFinishing systems because we can move carriers at different speeds when needed, from full-stop to speeds as high as 40 or even 65 fpm in non-process areas (and depending on the system series, with the heavier systems tending to move a little slower). IntelliFinishing bases its capacity measurements on carriers per hour and average parts per carrier. This measure accounts for the fact that different carriers can travel at different speeds per section and around the track. Carrier per-hour calculations consider your total output requirements, not just linear feet per minute. So, how can you anticipate the number of carriers your system will need to handle in an hour?

Calculating Parts Per Hour

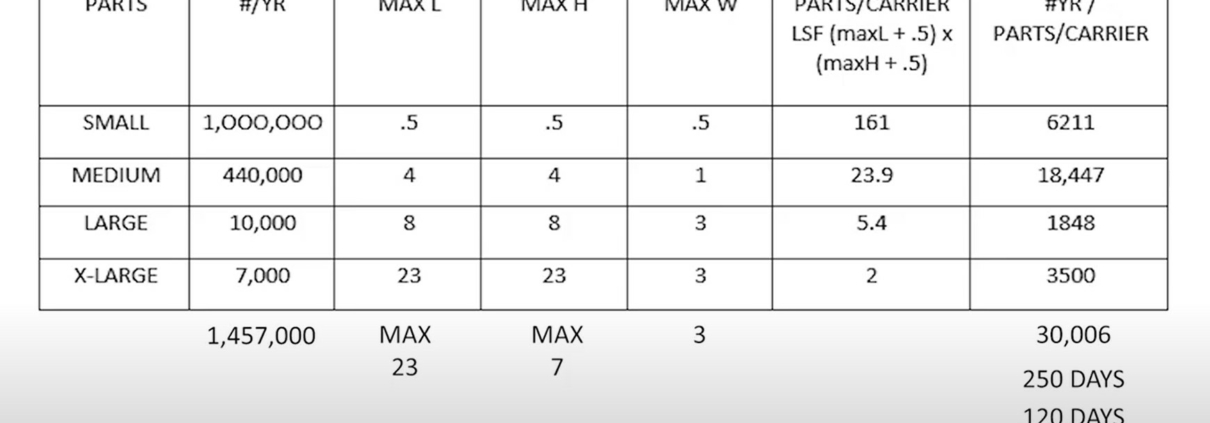

Calculating carriers per hour starts with calculating average parts per hour. If you have the means to estimate how many specific parts the system will need to finish with part dimension data per part, you can, of course, use this detail to calculate carriers per hour to a very granular level. Unfortunately, many companies process many, many parts, and estimating how many of each part per hour can be quite difficult. Perhaps an easier way to consider the volume of total parts is to use a category approach of small, medium, large, and extra-large parts. Dimensional data could be “estimated” by using the dimensions of the largest composite “small” part, “medium part,” etc. This method tends to underestimate parts per carrier, thus building in additional system capacity while ensuring a worst-case dimension per part size category. Once you know the estimated yearly volume of parts per size category with maximum estimated lengths and heights of each part category, it’s simple math to determine the average linear square feet per part category, and from this estimate, the number of parts that can be hung on a carrier traversing the finishing system. Don’t forget to add some spacing around each part. The most common way to add this spacing is to add a half-foot of length and height, respectively, to each “max size estimate” per part size category. Divide the derived square foot required per part into the carrier’s linear square foot capacity, and you’ll have the number of parts that can potentially be loaded per carrier.

Predictive Analysis Guides Forward Planning

Estimating capacity is a dynamic process that should adapt to your company’s growth. Your data should also be forward-looking, incorporating projections for the next five to eight years.

Here’s a link to a video we created to illustrate the process of estimating carriers per hour needed for a manufacturer with a wide range of part options: IntelliFinishing FAQ Series #14 – How Many Carriers per Hour Does Your System Need

Also, consider that the above calculations are assuming an ideal plant situation. You should consider what happens at your plant specifically. How smooth is the flow to the finishing system likely to be? Will there be gaps in wip available to be painted? To what degree will products need to be mixed on a carrier, causing variance in the average parts per carrier calculations? How about the customs at your plant? How likely is there to be gaps in manual operations during the day? As such, once you have a carrier per hour calculation, you might want to add to it a “fudge” factor. In other words, should you increase the CPH a bit to cover an imperfect plant? It’s not uncommon for companies to ask for systems ten to fifty percent faster than required, just to ensure they have enough capacity.

Scaling Finishing Operations With Confidence

Revolutionizing your finishing operations should not involve guesswork or leaps in logic. With a systematic method of calculating capacity, maximizing output, and future-proof planning, you can confidently scale your operations successfully, offering cost-effectiveness and efficiency in the long run.

Ready to optimize your finishing operations? Contact us at IntelliFinishing to discuss your needs and access a range of resources, including an automated spreadsheet that simplifies carrier capacity calculations and helps you evaluate your needs with precision.