*Batteries Not Included: Explore What Comes with Automated Finishing Systems Before You Purchase

When you make any new purchase, there’s always the consideration: ‘What else do I need?’ Batteries, for example, are necessary for so many things, from electronics to toys. In the world of automated paint systems, all those extras are a bit more complex. Many in the industry have questions about what’s part of the system and what’s not. To answer these burning questions, the IntelliFinishing Systems team put together this information for those that want to install our automated painting solutions.

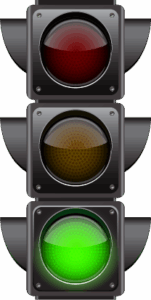

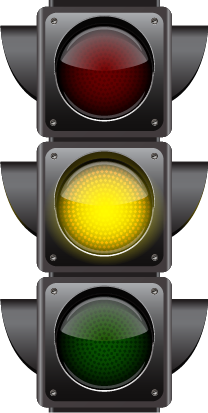

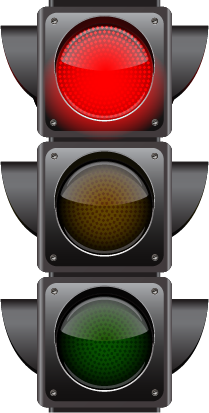

Below, you’ll find three categories regarding the state of inclusion in this handy guide: Always/Almost Always, Sometimes, or Not Usually/Never.

Always/Almost Always Included

Always/Almost Always Included

If needed for your finishing system, these components are usually part of the system.

First is a sophisticated control system. It integrates all the process equipment and the conveyor operation to enable tracking of every parts carrier. Each carrier can have different recipes to process a wider variety of parts versus other, more traditional conveyorized finishing systems.

Here are other individual elements that are usually part of the solution we provide.

- Friction-tube conveyor system with column or ceiling support options

- Pretreatment automated or manual wash systems

- Dry off and cure ovens

- Environmental rooms that surround booths with ideal HVAC conditions

- An experienced project team overseeing all subs/vendors that also coordinates the project from start to finish

- 24/7 help desk and warranty support

- Electrical installation

- Booth, process equipment, and conveyor mechanical installations

- RO (reverse osmosis) water system

- Trash disposal

- Fork-truck and scissor lift rental to facilitate system installation

- Software licenses and potentially a virtual or physical server to host the operating system

- Control Panels with VFDs (variable frequency drives), PLCs (programmable logic controllers), and internal wiring

- HMI (human-machine interface) control panels and emergency stop stations to operate the system with networked office computer visibility into system operation

More elements almost always included if needed, such as:

- Lifts at load or unload (if needed and/or for other reasons like to ascend or descend for high or low processes)

- Cooling tunnels

- VOC (volatile organic compound) flash chambers

- Masking or QC platforms

- Shot containment rooms

Sometimes Included but Often Purchased Independently

Sometimes Included but Often Purchased Independently

Next, let’s define the items that may come with the system, but many users of automated finishing systems purchase on their own.

Liquid or Powder Coating Booths

These booths include all application equipment. In our experience, most of our customers purchase these directly. We may supply only the booth in some scenarios, while users source application equipment from others. The application equipment consists of guns, reciprocators (and peripheral equipment to support the reciprocators), powder or liquid paint supply systems, mixing systems, a paint filter or reclaim system, etc.

Robots

We can provide robots if your powder coating or liquid coating solution specifies them. Typically, our customers purchase robots and software directly from the manufacturers. We then coordinate with that robotics company to exchange system data so that the robots are functional. Robot usage may involve loading and unloading as well as applying liquid or powder paint.

Shotblasts and Accessory Equipment

We usually quote the installation only in proposals, but we can source the shotblast, too.

Not Usually Included and Most Likely Require Third-Party Purchasing

Not Usually Included and Most Likely Require Third-Party Purchasing

The following pieces rarely are part of the systems we provide. However, they are typically necessary to deploy your painting system.

- Wastewater systems to meet local ordinances

- In-floor drain systems

- Automated chemical dispensing systems (integration capabilities)

- Compressed air systems

- The building or space and a suitable slab foundation

- Utilities: electrical, water, sewage, and natural gas service drops necessitate direct interaction with the local utilities

- All local licensing requirements from the location’s municipality or region

- Floor pitting and drainage systems

- Floor surface preparation

- Fire protection and suppression systems

- Product racking

- Burn off ovens or fluidized sand bends to clean off racking

- Scissor lifts or gantry arm hoists or cranes for lifting items to load height

- Paint testing equipment to meet paint application specifications

While you don’t need batteries for our systems, we’d certainly be happy to include them! From the lists above, you now have a better idea of all the necessary components for an IntelliFinishing automated painting system.

Learn more by watching our video highlighting our finishing systems for liquid and powder coating or for more information, contact us today.

Leave a Reply

Want to join the discussion?Feel free to contribute!