In today’s Information Age, the most valuable commodity in the world is no longer silver, gold, or oil—it’s data. What makes data so precious is its ability to help businesses optimize processes, marketing, products, services, and of course, revenues. So, you may ask, “What does this have to do with finishing systems?” Well, if you’re using a traditional automated finishing system with very limited control and no data logging, then you’re not optimizing your operations and potentially losing tens (if not hundreds) of thousands of dollars each year to inefficiencies. Switching to an IntelliFinishing System that includes smart controls enables a better workflow and better finish quality, saving both time and money.

Actionable Insights

Famed management consultant Peter Drucker had a saying, “you can’t manage what you can’t measure.” In other words, a business can’t improve its processes and achieve greater successes without clearly defined and quantifiable metrics. Or if you prefer Sherlock Holmes, the legendary detective had a famous line: “Data! Data! Data! I cannot make bricks without clay.” The idea is the same—you can’t achieve the desired outcome without first capturing and understanding the proper inputs. If you want to increase the consistency, quality, and throughput of your finishing process, then you need a flexible finishing system that also includes smart controls – delivering valuable data and actionable insights that can be used to enhance operations.

Smart Controls Drive Improvements

While many of today’s industrial machines now feature smart controls, the same can’t be said of traditional conveyorized finishing systems—most are commonly equipped with limited controls that offer no data logging or measurable analytics. But an IntelliFinishing system with smart controls allows operators to track parts as they move through the system. The system can log all production data of interest including pre-finish process settings and times per loadbar, part, or order; coating times and paint or powder usage and settings; carrier dwell times, speed per section, or status; dry off or cure oven timing, temperature, and trends; and more. The data is all stored in a database that can be customized into easy-to-read reports, tables, and graphs so that improvements to quality, productivity, and performance can be made.

Smart Features of IntelliFinishing

IntelliFinishing takes your finishing system to the next level. With IntelliFinishing, parts are processed according to each carrier’s selected recipe. Recipe’s can be fixed or customizable per your finishing needs. For example, the smart system uses recipe information to determine which cure oven lane the carrier of parts will enter to achieve optimal cure time but avoid slower curing items that can bottleneck the system. And while traditional monorail systems convey parts at the same feet per minute speed for the entire system and with limited abilities to adjust speed without negative consequences, an IntelliFinishing system can change blast, wash, cure, and non-process area conveyor speeds, settings, and times per carrier. An IntelliFinishing system also enables the adjustment of component variables, like wash sequence or pressure, oven temperatures, air turns, and timing—depending on the recipe. The system can run very dissimilar products back-to-back for a “Lean” product flow that can greatly reduce system WIP.

Of course, one of the key features of the smart system is the ability to track and record part data for product validation and analysis. The IntelliFinishing industrial software provides a view of your entire finish facility, part processes, and productivity from any HMI station or networked computer, with insights that enhance quality and increase throughput while facilitating production scaling as needed.

A Cost-Effective Finishing Solution

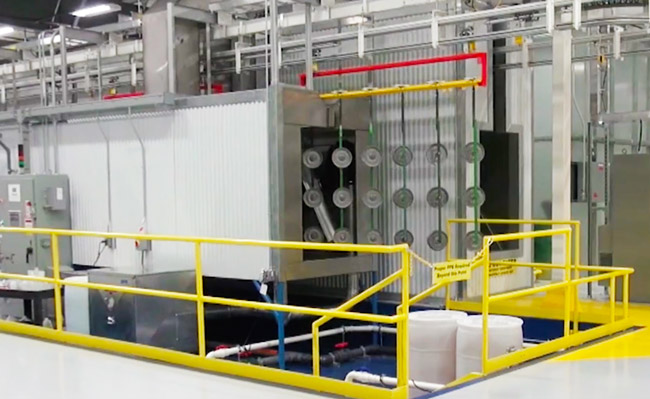

IntelliFinishing is a cost-effective, revenue-boosting finishing solution. It uses a friction-driven tube conveyor with extremely high uptime ratings, low maintenance requirements, and which eliminates chain-based part finish contaminations. The system also greatly reduces utility and overall costs to operate since there’s no need to heat up a chain conveyor continuously as it flows through ovens and our systems feature the most energy-efficient washers and ovens in the business.

Further, due to modular construction and recipe control, an IntelliFinishing system more easily adapts to future changes in processes, finishes, throughput requirements, or part profiles, ensuring facilities are ready for whatever comes next! To learn more, check out our video on smart controls.

We have replaced belts on regular scheduled maintenance and have only had one time since 2015 when we had a belt completely fail and come apart. As the system is designed, however, we were able to cut the belt free and continue running on three belts.

We have replaced belts on regular scheduled maintenance and have only had one time since 2015 when we had a belt completely fail and come apart. As the system is designed, however, we were able to cut the belt free and continue running on three belts.

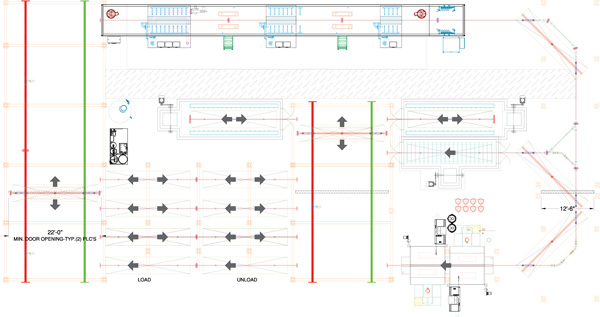

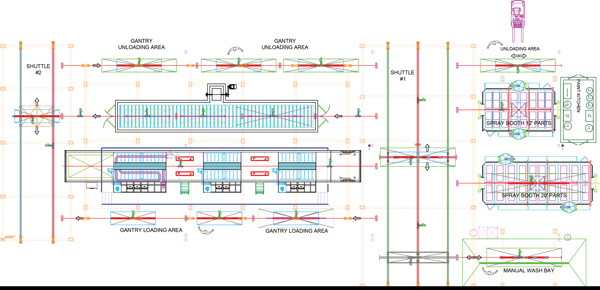

The MRI system features a 20-foot carrier and shuttle on the left-hand side of the system for transporting products from the load area, through an automatic and integrated sliding door into their unheated and uncooled added manufacturing space where automatic washing, dry-off and curing processes occur.

The MRI system features a 20-foot carrier and shuttle on the left-hand side of the system for transporting products from the load area, through an automatic and integrated sliding door into their unheated and uncooled added manufacturing space where automatic washing, dry-off and curing processes occur. Not all of MRI’s parts require finishing. They also use the system to just wash and dry metal parts that will be unfinished in the final assembled monitors. This greatly improves the overall quality of their sets by removing unwanted dust and oils – a process they used to do by hand.

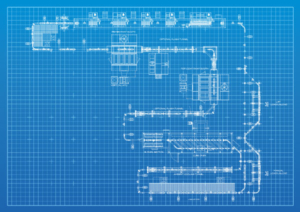

Not all of MRI’s parts require finishing. They also use the system to just wash and dry metal parts that will be unfinished in the final assembled monitors. This greatly improves the overall quality of their sets by removing unwanted dust and oils – a process they used to do by hand.  Depending on the size of the part, there are different flow paths through the system. This is caused because one of the two shuttles allows part only up to about half the size of the other shuttle. Since the majority of their parts are at or below 12-ft. in length, after being loaded in the loading lane, carriers proceed to the left onto a shuttle sized for up to 12-foot parts. This shuttle moves laterally from the loading lane to line up with the wash booth lane. From there the carrier can back up off the shuttle moving from left to right and go through a multi-stage automated wash booth lane. After wash, carriers flow onto a larger right side of the system shuttle and into one of their two liquid spray booths. After being coated, items back out of their respective booths and onto the larger shuttle again. The shuttle transports the parts laterally again up to the cure oven lane where they leave the shuttle and flow into the final cure oven. At this step, each carrier can have its own oven timing setting to maximize force cure quality, while eliminating chances of under or over curing products. Cure time is controlled by the system recipe selected at load per carrier. After curing, the carriers move once again to the first shuttle and laterally again up to the unload lane for final unload and the consequential return of the carrier via the large secondary shuttle back to the load area lane on the other side of the system.

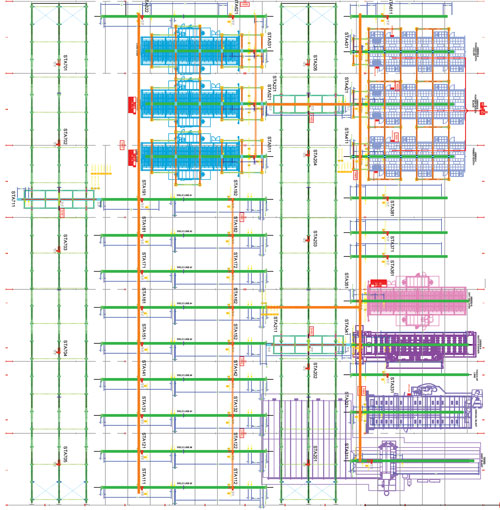

Depending on the size of the part, there are different flow paths through the system. This is caused because one of the two shuttles allows part only up to about half the size of the other shuttle. Since the majority of their parts are at or below 12-ft. in length, after being loaded in the loading lane, carriers proceed to the left onto a shuttle sized for up to 12-foot parts. This shuttle moves laterally from the loading lane to line up with the wash booth lane. From there the carrier can back up off the shuttle moving from left to right and go through a multi-stage automated wash booth lane. After wash, carriers flow onto a larger right side of the system shuttle and into one of their two liquid spray booths. After being coated, items back out of their respective booths and onto the larger shuttle again. The shuttle transports the parts laterally again up to the cure oven lane where they leave the shuttle and flow into the final cure oven. At this step, each carrier can have its own oven timing setting to maximize force cure quality, while eliminating chances of under or over curing products. Cure time is controlled by the system recipe selected at load per carrier. After curing, the carriers move once again to the first shuttle and laterally again up to the unload lane for final unload and the consequential return of the carrier via the large secondary shuttle back to the load area lane on the other side of the system. Load Trail had a significant challenge finishing its agricultural trailers. The trailers range in size from 24 to 53 feet in length and weigh up to 10,000 lbs. To help them solve the problem of powder coating these trailers and to streamline their finishing, we installed a

Load Trail had a significant challenge finishing its agricultural trailers. The trailers range in size from 24 to 53 feet in length and weigh up to 10,000 lbs. To help them solve the problem of powder coating these trailers and to streamline their finishing, we installed a  the shuttle, it allows for a massive system, but one that still saves space because it does not require any bulb turns or return sections of chain track.

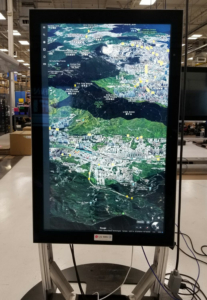

the shuttle, it allows for a massive system, but one that still saves space because it does not require any bulb turns or return sections of chain track.  Manufacturing Resources International designs, engineers and fabricates BoldVu® LCD displays, maintaining the industry’s largest install base of outdoor LCDs with deployments in over 50 cities around the globe.

Manufacturing Resources International designs, engineers and fabricates BoldVu® LCD displays, maintaining the industry’s largest install base of outdoor LCDs with deployments in over 50 cities around the globe. The system can handle parts up to twenty feet long by five feet wide by eight feet tall, and up to 800 pounds per loadbar.

The system can handle parts up to twenty feet long by five feet wide by eight feet tall, and up to 800 pounds per loadbar. The addition of an IntelliFinishing system has brought a wide range of benefits to MRI’s operation, including:

The addition of an IntelliFinishing system has brought a wide range of benefits to MRI’s operation, including: Wash recipes allow for different types of metals or parts with different pretreatment requirements to each have their own

Wash recipes allow for different types of metals or parts with different pretreatment requirements to each have their own

Imagine your outsourcing of finishing has grown over the years to about $1 million per year with local (or maybe distant) custom-coaters. How much money could an automated, in-house system save you per year that would justify the relatively large capital expenditure?

Imagine your outsourcing of finishing has grown over the years to about $1 million per year with local (or maybe distant) custom-coaters. How much money could an automated, in-house system save you per year that would justify the relatively large capital expenditure? Depending on the types of product you need coated, even a relatively traditional monorail could be paid for in about two to four years for this amount of savings. After that, it would be savings that go to your bottom-line profits. Most simple monorail systems likely cost between $500,000 and $2,000,000, but this is entirely dependent on process requirements for pre-finish steps such as shot-blasting, washing, and dry-off ovens, as well as for the type of booths and cure ovens and specific conveyor requirements for the part dimensions and weight considerations.

Depending on the types of product you need coated, even a relatively traditional monorail could be paid for in about two to four years for this amount of savings. After that, it would be savings that go to your bottom-line profits. Most simple monorail systems likely cost between $500,000 and $2,000,000, but this is entirely dependent on process requirements for pre-finish steps such as shot-blasting, washing, and dry-off ovens, as well as for the type of booths and cure ovens and specific conveyor requirements for the part dimensions and weight considerations. Ultimately, this is just a first-cut calculation to begin the process of considering a new finishing system. If your calculus indicates you might benefit from a system, the next step is to start finding a vendor to draft up a layout and determine a budgetary or formal quote.

Ultimately, this is just a first-cut calculation to begin the process of considering a new finishing system. If your calculus indicates you might benefit from a system, the next step is to start finding a vendor to draft up a layout and determine a budgetary or formal quote. However, this dip in demand has us here at IntelliFinishing, along with our system partners, raring to go.

However, this dip in demand has us here at IntelliFinishing, along with our system partners, raring to go. Of course, each situation is unique and would require in-depth analysis, but why not check into bringing your outsourcing in-house? (More on this topic in the coming weeks!) You’d also likely see far less rejects and defects, a reduction in transportation costs, faster turn times, less WIP, and better finish quality.

Of course, each situation is unique and would require in-depth analysis, but why not check into bringing your outsourcing in-house? (More on this topic in the coming weeks!) You’d also likely see far less rejects and defects, a reduction in transportation costs, faster turn times, less WIP, and better finish quality. And, finally, if you have or are considering a system that consumes a larger facility footprint than an IntelliFinishing System can provide, you are missing an opportunity to use that space for other revenue producing activities or to have a smaller facility that costs less to build, own or lease.

And, finally, if you have or are considering a system that consumes a larger facility footprint than an IntelliFinishing System can provide, you are missing an opportunity to use that space for other revenue producing activities or to have a smaller facility that costs less to build, own or lease.