When Should You take a Site Visit when Planning a New Finishing System?

Adding an automated finishing system to your operation can have a tremendous impact on efficiency, productivity and quality – and that’s why you’ve made the choice to invest in an industrial finishing system that matches your unique needs. It’s also critical to get it right…

Choosing a Conveyor

Conveyors for Finishing Systems The selection of a conveyor for your powder coating system or liquid paint system at your manufacturing plant should be based on the features and benefits of each of the conveyors, part and process requirements, as well as your business goals….

Old Technology. New Technology.

Are you interested in purchasing new technology that can grow with your company and save you lots of money in unnecessary costs? We want to share with you a few of the advantages you can expect when replacing your traditional Power & Free or Monorail systems with the newest technology for Industrial paint system replacement.

Tour an Active Construction Site

Kevin Howe, IntelliFInishing Project Manager, just finished the setup on IntelliFinishing’s latest project installation. During the construction process he took us on a brief tour.

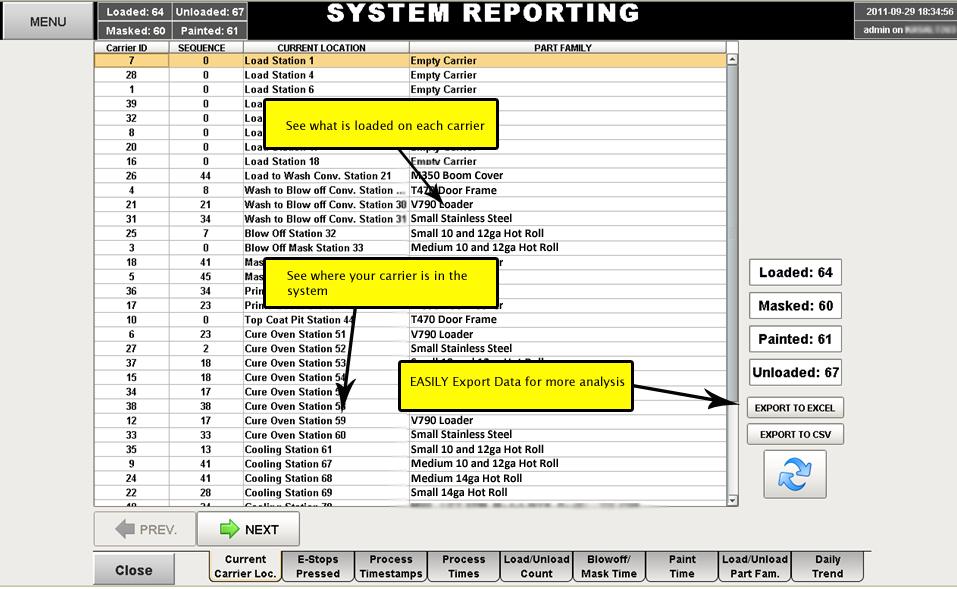

Using Big Data To Track Your Parts

Production data is key to making sure your system is efficient and profitable. Konnection software turns your data into easy to read graphs detailing the information you have in a reviewable database created by your real-time production.

A Plan for Every Part

…an IntelliFinishing system offers capabilities in ONE LINE that would take MULTIPLE LINES for traditional systems. Customers have been amazed at what can be accomplished with layouts that are not limited by a one-way, one-speed conveyor.

Part I: Changing the “Game”! – Improving Paint System Design

Once you understand the IntelliFinishing system, it will shatter your preconceived notions and known limitations of what a paint finishing system has been.

A “Chainless” Power & Free Conveyor?

The separate motors also turn off and on the individual conveyor sections when there is a part present making this system more energy efficient because the full system isn’t always running, only the process areas being used at the given time.

What is a Recipe-Based Finishing System?

There is no longer a need for batching your whole line with like parts to get quality.

Search this blog

Get email updates

Archives

- May 2024

- April 2024

- August 2023

- May 2023

- April 2023

- March 2023

- June 2022

- May 2022

- April 2022

- November 2021

- October 2021

- September 2021

- April 2021

- March 2021

- January 2021

- October 2020

- August 2020

- June 2020

- May 2020

- February 2020

- January 2020

- December 2019

- October 2019

- September 2019

- June 2019

- May 2019

- March 2019

- February 2019

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- December 2016

- June 2016

- May 2016

- April 2016

- February 2016

- January 2016

- September 2015

- June 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- August 2014

- June 2014

- May 2014

- April 2014

- August 2013

- July 2013

- March 2013

- October 2012

- September 2012

- March 2011

- February 2011

- January 2011

- October 2010