In the world of manufacturing, IntelliFinishing stands out by providing customized finishing systems. Our unique solutions are not only efficient and flexible, but also meticulously tailored to meet manufacturers’ specific process requirements.

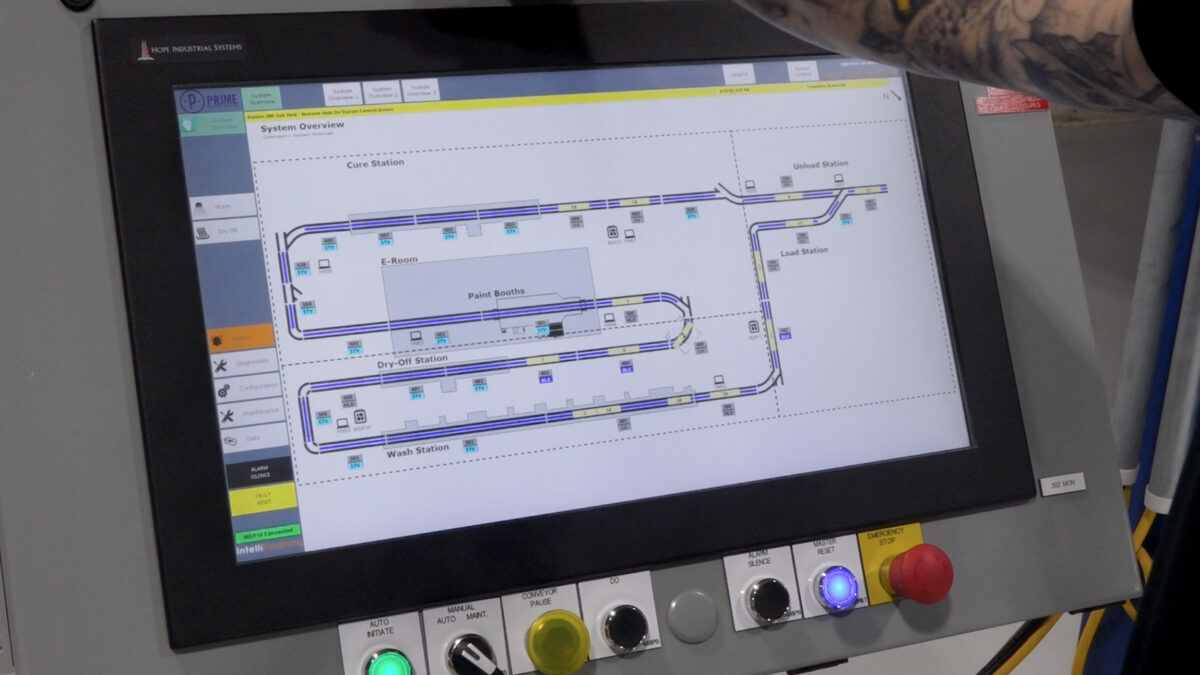

Our recipe-based smart controls are central to the IntelliFinishing difference, propelling our services beyond industry standards. This key differentiator is paving the way for unparalleled customization and adaptability in manufacturing operations.

Revolutionary Control with Recipes

At the core of IntelliFinishing’s innovation is our recipe-based control technology. It affords manufacturers the ability to tackle an extensive variety of part sizes and shapes, like Prime Powder Coating’s facility expansion that can now accommodate components up to 23 feet long and 4,000 pounds. Despite the demand in variety, our systems deliver meticulous accuracy across every phase of the custom finishing process — from wash cycle to the final cure.

Gone are the days of being confined to the traditional loop of conveyors. IntelliFinishing’s layouts, empowered by our smart controls, allow carriers to move both forward and backward. The strategic use of reverse motion and deadheads significantly cuts down on the space typically lost to wide turns. This not only conserves valuable square footage, but also amplifies operational efficiency, optimizes resource and equipment use, and facilitates capabilities beyond the reach of conventional systems.

Furthermore, our systems’ streamlined operations lead to labor optimizations. Clients frequently report a reduction in shifts and associated costs, bolstering a more economically lean manufacturing environment. In fact, one customer reported reducing shifts from three to one after installing an IntelliFinishing system.

Unmatched Flexibility for Any Industry with Smart System Controls

Our smart control system is the driving force of IntelliFinishing’s distinction. This breakthrough technology bestows unprecedented flexibility within the conveyor system, permitting individual control over each carrier’s movement. It’s this granular level of control that allows your finishing operations to be as varied as the parts you process, maintaining quality and efficiency at all times.

The ability to change speeds in a process or to alter treatment times and stages enables an optimal process per carrier, redefining the usual finishing paradigm of sorting like parts and finishing them on different systems built for those parts to allowing one system to be able to handle all the parts in an as needed and leaner process. Our automated systems have proven their versatility across a variety of industries, from aerospace to agricultural and construction equipment, automotive parts to defense machinery. IntelliFinishing systems are engineered to adjust to the ongoing evolution of products, pretreatments, finishes, and other industrial demands, demonstrating our commitment to innovation.

The IntelliFinishing Difference

IntelliFinishing stands at the forefront of the finishing systems industry, delivering comprehensive solutions that redefine efficiency and customization. Our commitment to a turnkey approach extends from the meticulous design phase through to a seamless installation, ensuring every system is fine-tuned for optimal energy efficiency and intelligent operation. With IntelliFinishing, you’re not just upgrading to a new system; you’re investing in a future-proof operation that can effortlessly adapt to the evolving landscape of manufacturing with a diverse handling capacity, on-the-fly adaptability, and seamless integration into current processes.

We set ourselves apart by revolutionizing traditional finishing systems with our unique conveyor system and smart controls, providing an unmatched level of customization and operational flexibility. This approach can drastically reduce installation time and often creates a smaller system footprint, enabling your operation to pivot and scale with agility.

IntelliFinishing is dedicated to empowering manufacturers with greater control, efficiency, and adaptability in their finishing systems. We craft each detail to precisely meet the dynamic needs of modern manufacturing environments, but with the ability to change the process as needs and requirements change. With IntelliFinishing, you gain a partner committed to shaping the future of finishing, where your specific needs dictate the capabilities of your finishing system.

A great way to learn more about IntelliFinishing is to visit our Videos page or if you’re ready to implement your new finishing system with recipe-based smart controls get in touch today!

Related posts

Search this blog

Get email updates

Archives

- May 2024

- April 2024

- August 2023

- May 2023

- April 2023

- March 2023

- June 2022

- May 2022

- April 2022

- November 2021

- October 2021

- September 2021

- April 2021

- March 2021

- January 2021

- October 2020

- August 2020

- June 2020

- May 2020

- February 2020

- January 2020

- December 2019

- October 2019

- September 2019

- June 2019

- May 2019

- March 2019

- February 2019

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- December 2016

- June 2016

- May 2016

- April 2016

- February 2016

- January 2016

- September 2015

- June 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- August 2014

- June 2014

- May 2014

- April 2014

- August 2013

- July 2013

- March 2013

- October 2012

- September 2012

- March 2011

- February 2011

- January 2011

- October 2010