- Home

- The Difference

- Deadhead Capabilities

Deadhead Capabilities Offer Flexiblity for Paint Systems

Deadheads can be added to your complete finishing system to add flexibility in almost all aspects of your paint system.

A deadhead is similar to a u-turn except the carrier doesn't actually make a turn; instead it just reverses to move in the opposite direction. This is possible because the conveyor used in an IntelliFinishing system does not use a chain. It is a friction-driven conveyor that propels the carrier with a spinning tube. This unique technology allows the carrier to easily move forward and reverse at any point in the system.

Layout Options

The addition of deadheads can offer nearly unlimited layout options. Whereas, traditional systems with monrail conveyors or power and free conveyors offer minimal layout options.

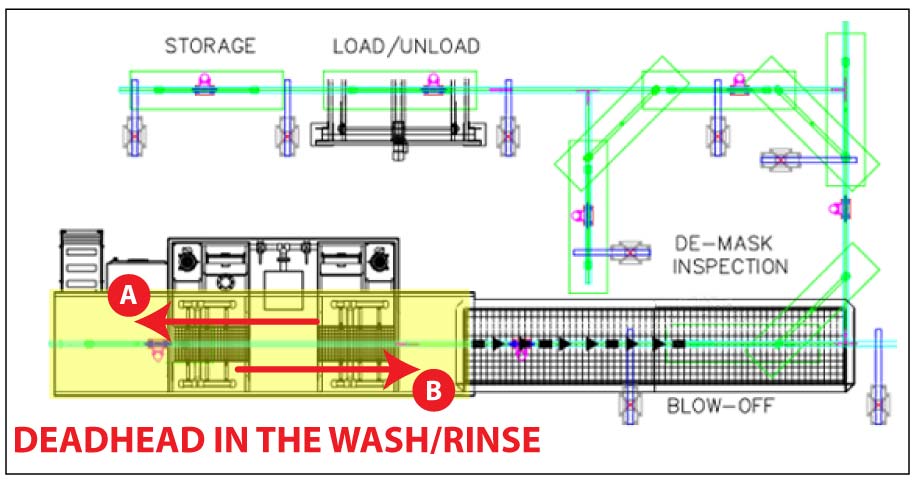

Deadhead with Process Equipment

One IntelliFinishing customer was told no traditional monorail or power and free paint system would fit their existing space. By adding a deadhead at the wash/rinse, we fit their complete finishing system in the existing space.

As seen in the diagram, parts move into the wash/rinse in direction A, then reverse directly out of the wash/rinse in direction B. Again, this is made possible by the unique conveyor used by an IntelliFinishing system with no chain/return chain. (Click the image to enlarge.)

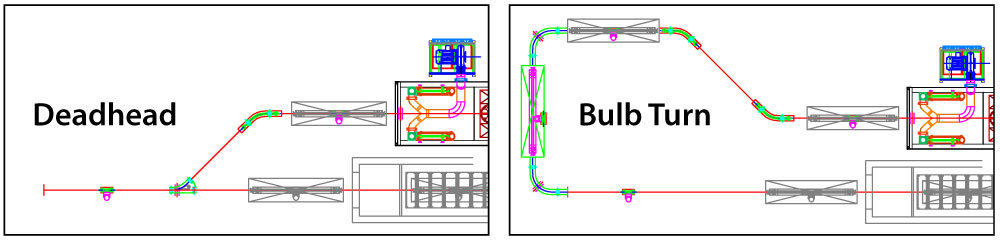

Deadhead Turns

Deadheads can also be used to significantly reduce the amount of floorspace required for a finishing system. The turn on a traditional system running large parts on a long load bar requires a large bulb turn, taking up a large portion of floorspace. While on an IntelliFinishing system, a deadhead can be added to re-orient the part and direction of travel in a much smaller space.

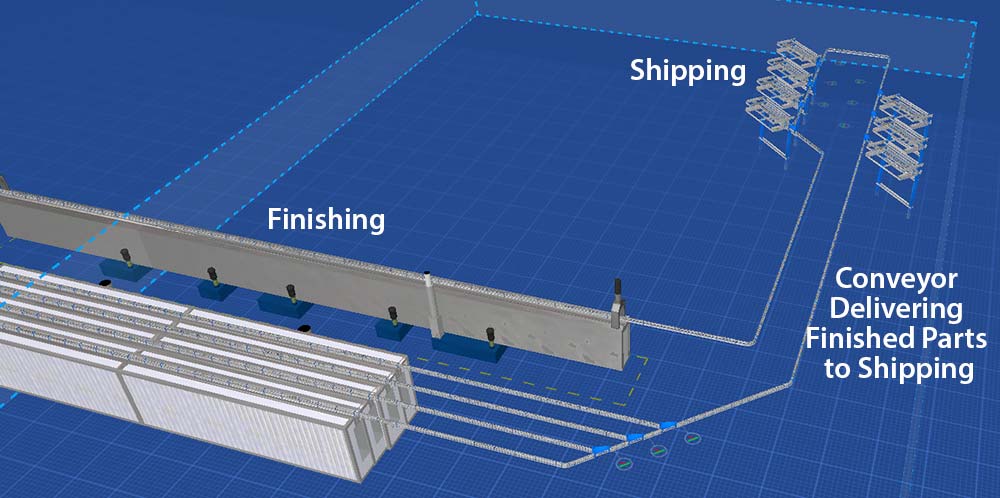

Deadhead for Point of Use

Expanding your finishing system to point of use can be cumbersome when using traditional chain conveyors which require return chains. An IntelliFinishing paint system has no chain (or return chain) and can go in forward and reverse, making it much easier to expand your system to point of use.

For example, we designed an IntelliFinishing system for one customer which expanded their conveyor from the finishing process directly to the shipping department. Because an IntelliFinishing system has independently controlled zones, carriers can move at different speeds at any point in the system. The section of conveyor from finishing to shipping was created so the carriers would move faster through the non-value added areas. Additionally, some customers utilize removable load bars teamed with custom racks to easily load parts.This allows them to preload parts, reducing the time needed to position and stage parts.