Maintenance of Overhead Conveyor for Complete Paint Systems

Minimal maintenance is required for our overhead friction-driven conveyor. This conveyor is an alternative to power and free conveyors. The following videos provide a brief overview demonstrating the maintenance required for an IntelliFinishing paint system conveyor.

Friction-driven conveyors do not have a chain and use a spinning tube to propel the trolleys. The conveyor, manufactured by IntelliTrak, touts an up-time of 99%.

In addition to a reduction in maintenance costs and time to maintain a conveyor, the friction-driven conveyor allows for maintenance to occur in a zone without disrupting or stopping the whole system. Therefore, throughput and productivity remains at a high level with an IntelliFinishing paint system.

The Importance and Ease of Preventive Maintenance

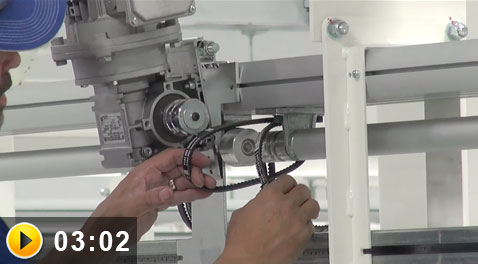

Preventive maintenance is an important part of maintaining your conveyor over its life. In this video we show you how to maintain the drive belts.

Maintaining the Drive Belts

Four drive belts are located at each VFD on the automated finishing system. They are placed around the stainless steel tube/shaft to enable the friction-driven spinning of the tube to move the trolleys (which are transporting the load bars) throughout the automated finishing system. The belts should be checked for wear every six months. Belts should be checked for imperfections (such as unraveling) or factory defects. When replacing a belt you can simply cut the belt that needs to be replaced and wait for a break in production of after-hours to install the replacement belt. There are two belts on either side of each VFD. Once you cut the belt away it will leave a gap. The gap is perfectily fine until the replacement belt is installed and the trolley will still be able to travel across the shaft. It is important to keep the force distributed evenly on both sides of the partable shaft to keep the tension evenly distributed, so you would not want to run the system with both belts removed from one side of the shaft.

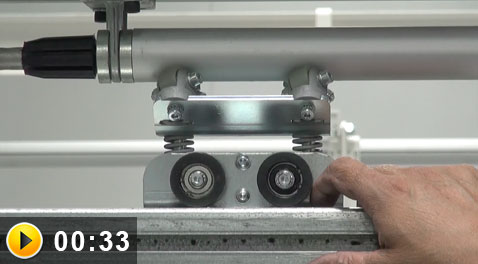

Maintaining the Connectors – Nuts and Bolts

Once a year you should review the following bolt connections in your system to make sure they are tight:

- bolt connections

- tap-tight nuts

- rectangle nuts

Split-lock washers and nylock nuts are used to ensure stability in this system. At installation, the nuts are match-marked to the washers to make sure the connections are tight. Tap-tight nuts are used to connect the structural steel beams of the system to the top of the track that the carriers will travel on. Rectangle nuts connect the structural steel to the bottom of the load rail. They are inserted into the slotted part of the track or steel frame and then turned to lock into place to keep the track secure.

Regular preventive maintenance as suggested in this video should keep your industrial finishing system for liquid paint or powder coating moving without incident for many years.